It's new. It's connective.

The smart gearbox.

Mechatronic drive systems that can collect and communicate information independently are fundamental to the IIoT. WITTENSTEIN alpha is now the first manufacturer of components to offer smart gearboxes as standard – gearboxes with cynapse®. The integrated sensor module enables Industry 4.0 connectivity.

Easy to integrate into existing drive solutions

Gearboxes with cynapse® are identical to the existing models in terms of design, size and contour. Drive solutions which have already been designed hence need no further modification. It is the sensor module integrated in the smart gearbox that makes the difference.

Whitepaper: Smart drive systems and digital services in the Industrial Internet of Things

Highlights

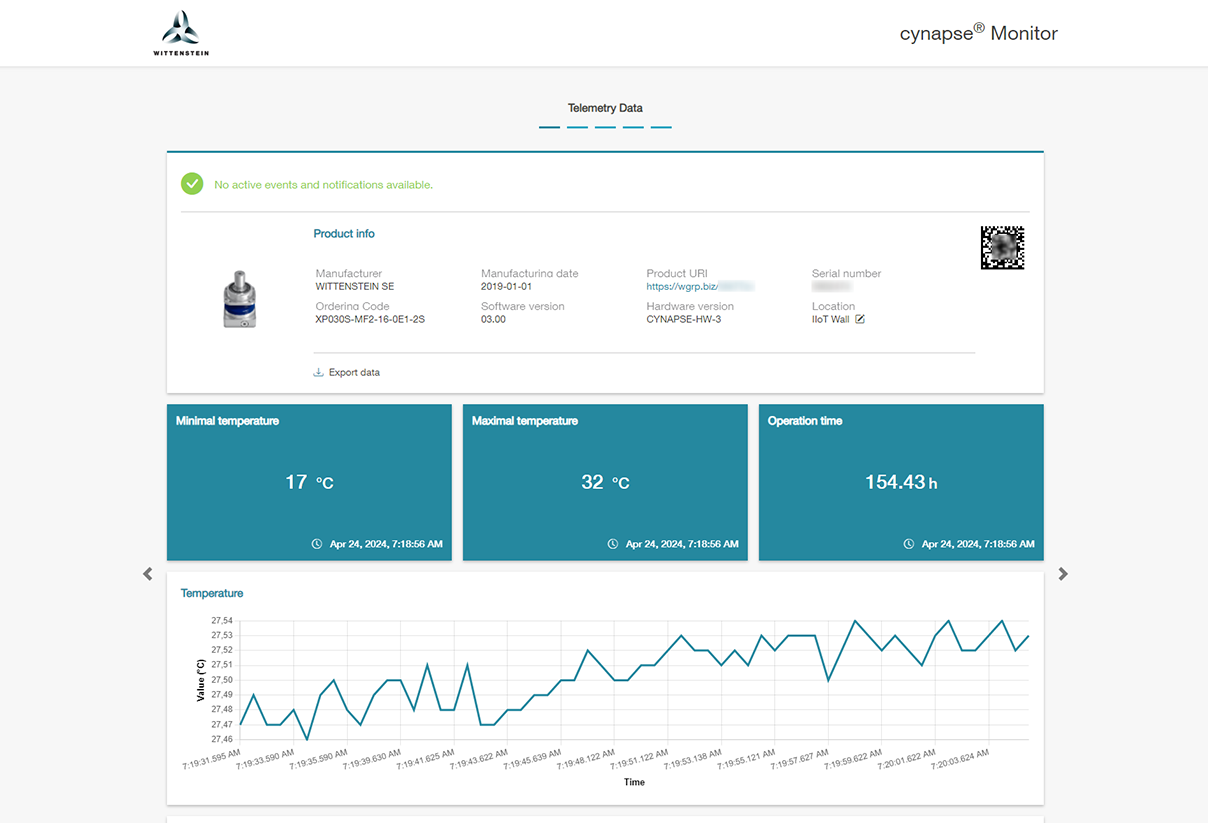

Product identification

The digital identification plate contains all relevant data needed for clear identification of your components.

Data logger

Data is collected and stored throughout your component’s lifecycle:

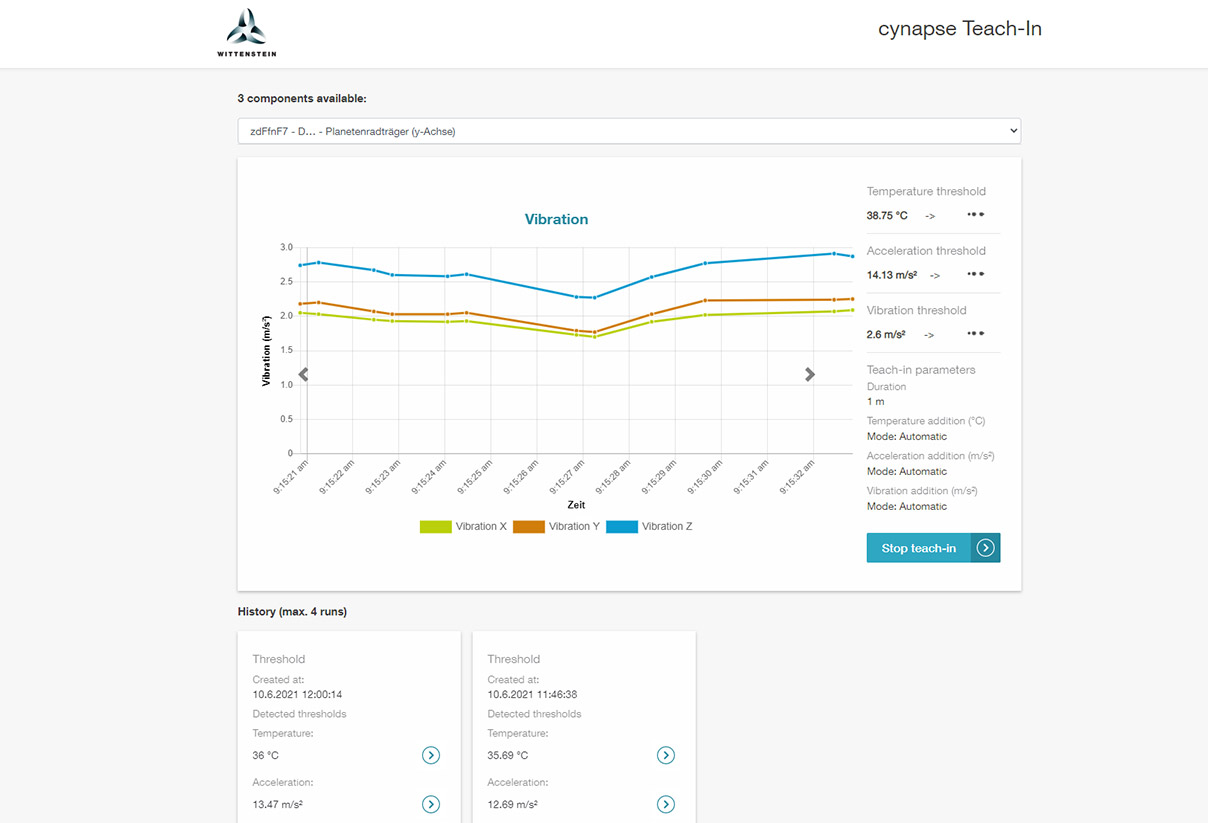

Temperature, vibration, mounting position and acceleration

Threshold monitoring

Sensor values are easy to monitor based on predefined or customized thresholds.

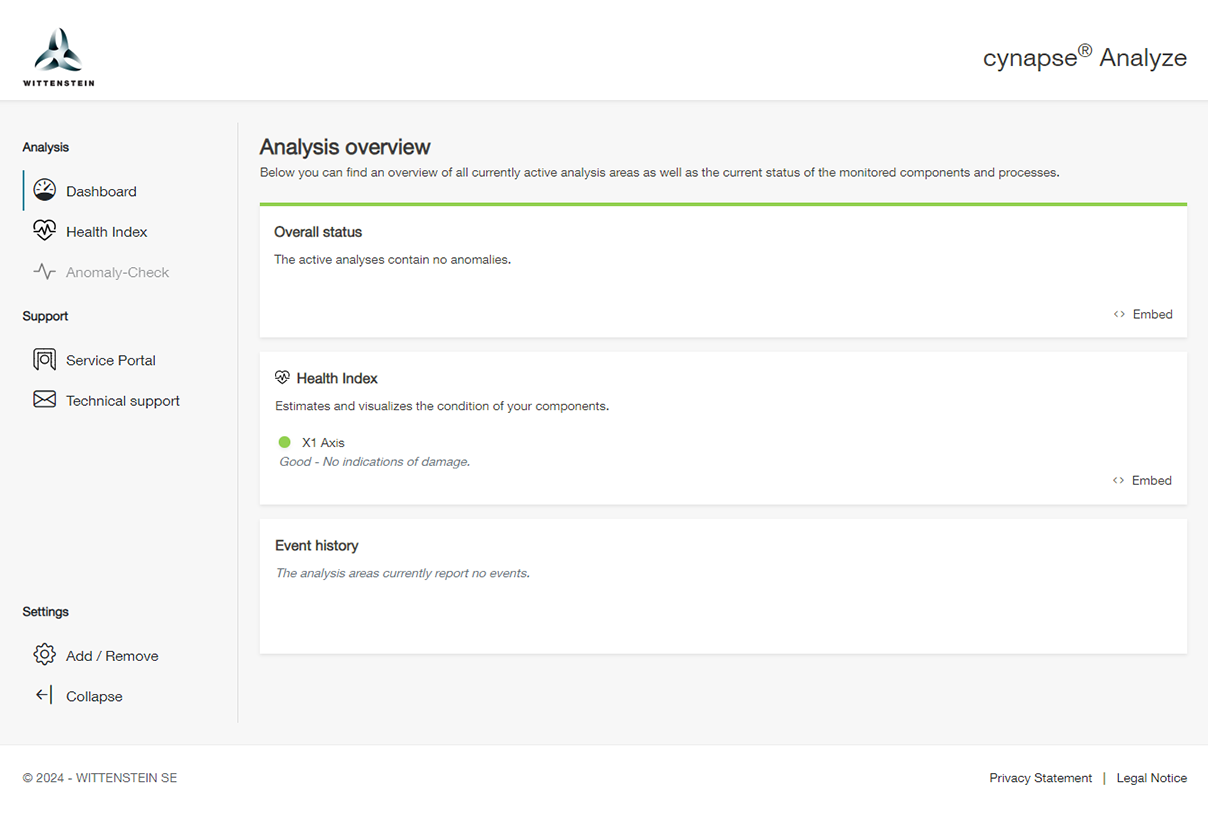

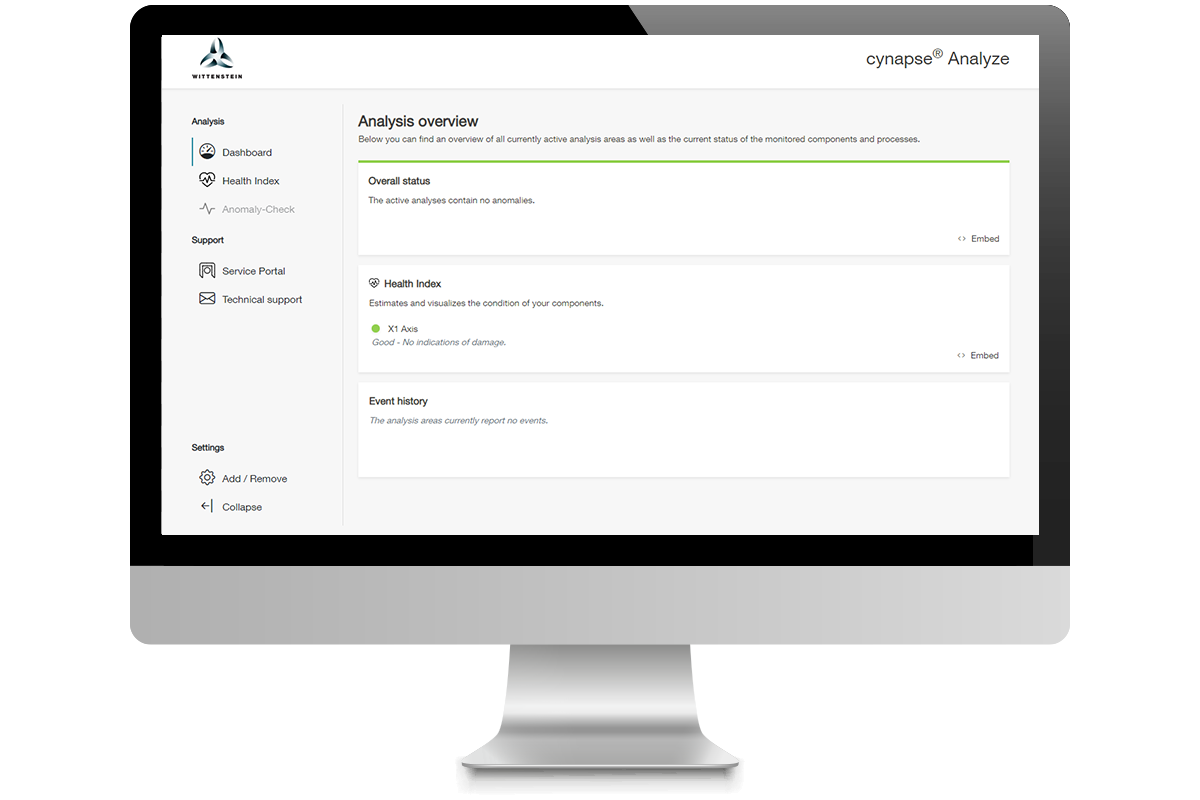

Smart Services

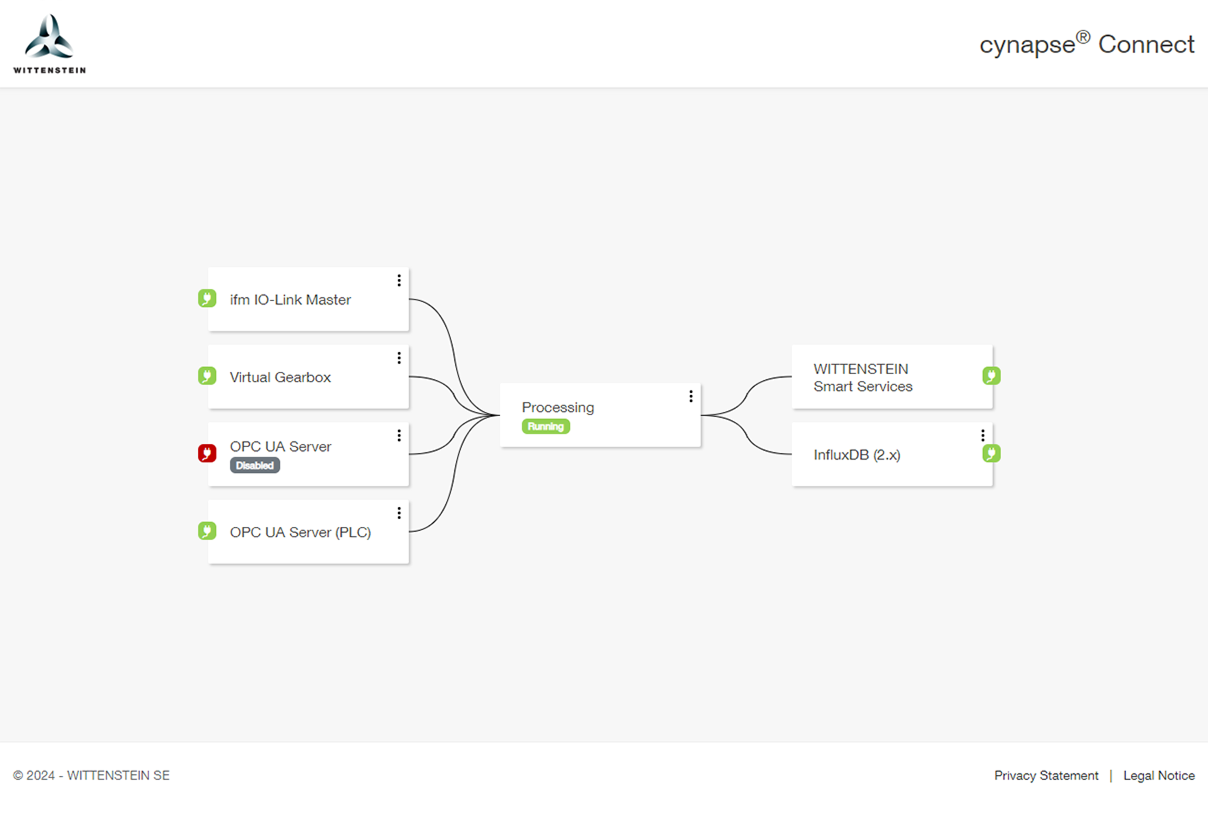

From gearbox to IIoT

The data which is generated in this way flows to the IIoT using the standardized connectivity of the IO-Link interface and an IO-Link master with a fieldbus interface. There – and in the machine’s immediate environment – this information can be used, for instance, in condition monitoring or predictive maintenance applications. Gearboxes with cynapse® thus provide universal connectivity – to their own machine infrastructures as well as to all standard IIoT platforms.